14 December 2022

From conventional to digital power line inspections: using autonomous drones and AI

Using Beyond Visual Line of Sight (BVLOS) drones and robots to improve asset inspections.

Context

Elia Group owns and operates around 19.000 km of high-voltage lines in Belgium and Germany. These power lines are inspected and maintained on a regular basis to always ensure the reliable security of supply.

The BVLOS Drone Project is testing the hypothesis that autonomous drones with embedded data collection systems can effectively replace helicopters for asset inspections, with an objective to cover and gather visual data over distances of up to 100-200 km.Utilizing autonomous drones reduces risks, saves time, cuts CO2 emissions, and lowers costs associated with manual inspections. In 2021, the initiative marked a milestone by conducting the first official autonomous BVLOS flight in Belgium, employing a drone of substantial capacity (87 kg).

Link to the video

Why this project?

The project's inception is rooted in addressing two key challenges:

- Ensuring the uninterrupted security of electricity supply.

- Modernizing the inspection process for heightened efficiency and safety.

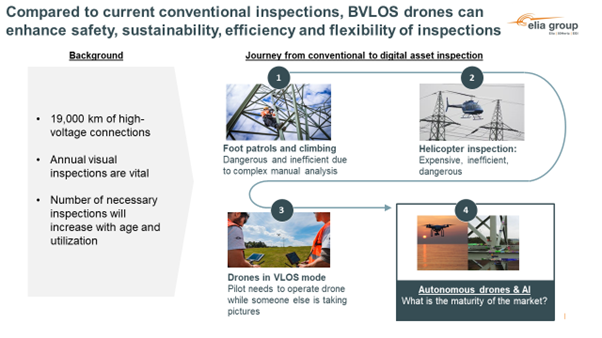

Traditionally, asset inspections are characterized by:

- Manual foot patrols conducted twice annually, involving physical inspection and binoculars.

- Helicopter surveys of the entire grid every one to three years, utilizing high-resolution cameras for detail, infrared for hotspot detection, and LIDAR scans for vegetation management.

Visual inspections including foot patrols by technicians and engineers will remain as they contribute to the training of our experts and are important to keep expertise about the grid.

However, helicopter inspections are expensive, inefficient, inflexible, time consuming, unsustainable, and entail major risks for the assets and employees. We foresee that helicopter inspections and “manual” assessments of those helicopter inspections could be substituted by autonomous drones and artificial intelligence.

The introduction of autonomous BVLOS drones aims to transform the process by:

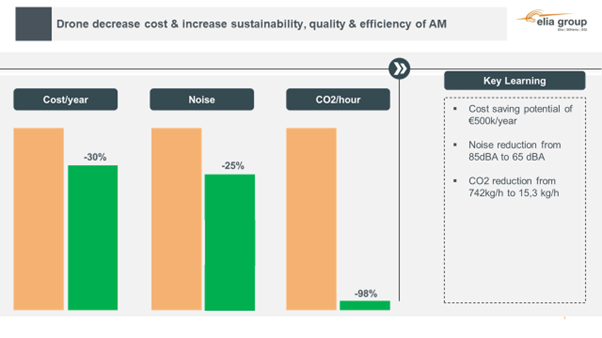

- Significantly reducing operational costs, estimated at over 200.000 euros annually for helicopter inspections.

- Enhancing safety for personnel by minimizing the need for manual tower climbs and reducing helicopter-related risks.

- Increasing the flexibility and frequency of inspections, thus improving overall efficiency, and reducing environmental impacts through lower CO2 emissions and noise.

More specifically, autonomous drones together with AI can substitute conventional power line inspections of foot patrol and helicopter inspections. Autonomous and digital inspections entail drones in BVLOS mode (Beyond Visual Line of Sight) that carry high-resolution cameras for detailed inspections of damages such as rust, LIDAR laser scans and photogrammetry scans for vegetation management and the development of 3D Models, infrared cameras for detecting thermal damages such as hotspots, and an AI that is capable to of evaluate evaluating the data that is captured to automate the analysis of damage detection.

Approach

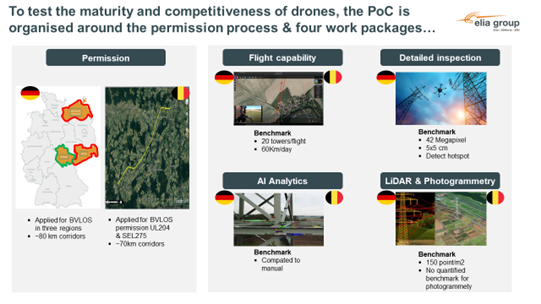

In late 2020 and early 2021, the project initiated its first BVLOS flights for asset inspections in Germany and Belgium, aiming to achieve two primary objectives:

- Automation of Data Capture: The project seeks to replace traditional helicopter inspections with autonomous drone inspections, streamlining the data capture process for inspecting transmission assets.

- Digitalization of Data Analytics: Additionally, the project aims to digitalize data analytics by developing an algorithm capable of effectively detecting defects on overhead lines and pylons.

To accomplish the first goal, Automation of Data Capture, the project outlines a series of validation steps:

- Conducting long-distance flights spanning 75-120 km to demonstrate the viability of substituting helicopter inspections.

- Performing detailed asset inspections using drones equipped with high-resolution cameras to identify damages such as rust.

- Utilizing LIDAR laser scans for vegetation management, generating 3D models to calculate distances between assets and vegetation.

- Creating a digital twin for infrastructure mapping and assessment through photogrammetry, a novel technology for 3D modeling.

- Conducting thermal analysis using infrared cameras to detect anomalies such as hotspots.

The project's milestones include the first BVLOS drone test in Germany in 2021, covering 80 km autonomously and incorporating thermography, photogrammetry, and high-quality image recognition. Subsequently, the first official autonomous BVLOS flight in Belgium demonstrated the drone's competitiveness compared to helicopter inspections, flying over 120 km in under two hours and yielding higher resolution output for detailed inspections. Estimated cost savings of over 600k euros per year were achieved, facilitating more frequent visual inspections.

Key findings from the tests include:

- Sufficient autonomy for inspecting multiple towers over distances exceeding 100 km, with payloads offering functionalities comparable to helicopters.

- Successful integration of hovering and long-distance flight, with image quality suitable for AI image recognition (e.g., rust identification).

- High quality of thermography and lidar inspections during autonomous flight.

For the second goal, Digitalization of Data Analytics, the project focuses on developing, testing, and benchmarking AI-driven analysis of data captured by autonomous drones. The algorithm will be collaboratively developed with external suppliers, while in-house algorithms will be compared to vendor solutions Elia is currently testing with VLOS drones.

Next steps

The project's next phase will involve expanding the current work package into a new project, centered around the Asset Management Moonshot project. While the exploratory proof of concept for testing BVLOS flights for post overhead line incident verification on the ground remains scheduled as outlined, additional components and work packages will be introduced. These will include the testing of new technologies aimed at achieving the objective of identifying the cause of incidents within a 10-minute timeframe.

Partners

|

|

|

|