05 December 2022

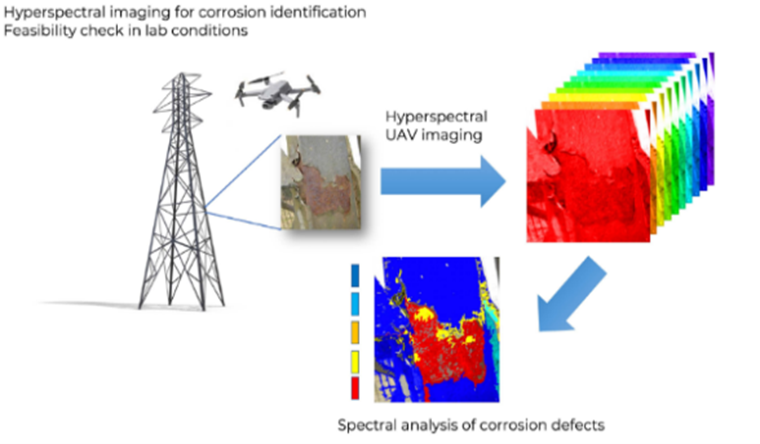

Hyperspectral camera for condition assessment of painted metallic towers

Metallic towers, one of the main components of overhead lines, rust over time. This project aims to find out whether there is any technology out there that can detect rust behind the painting in a non-destructive way?

Why this project

Metallic towers, one of the main components of overhead lines, rust over time. Despite applying paint roughly every 17 years to inhibit the process, corrosion continues and therefore impacts the stability of the towers. It is critical to smooth the replacement by detecting the level of corrosion of the towers as one of the main deterioration factors. Classifying corrosion is not trivial and requires detailed climbing inspection.

Approach

Back in 2021 we started technology market research and were looking to answer the below question:

Is there any technology out there that can detect rust behind the painting in a non-destructive way?

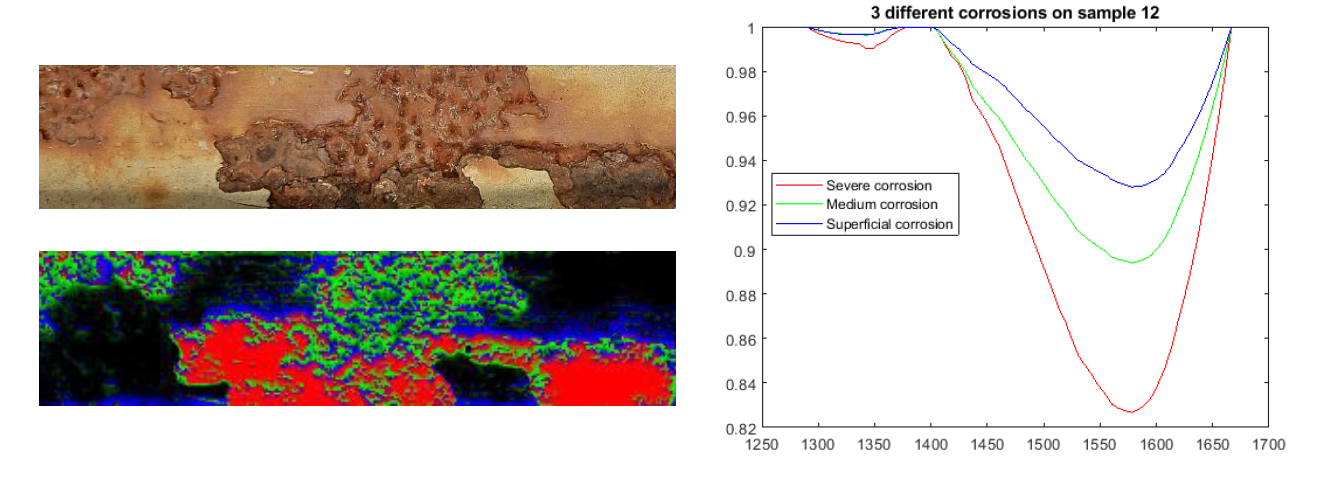

We were particularly keen to find a tool that would be able to detect corrosion that had developed in metallic towers including corrosion that might be hidden by a layer of paint. Furthermore, we wanted to investigate whether there might be some form of technology that could accurately classify the severity of rust patches into different types (e.g. superficial corrosion, medium or severe corrosion).

Investigations led us to focus on hyperspectral camera which captures reflections from across the electromagnetic spectrum, using this information to identify and classify the chemical properties of the material or object under investigation. This contrasts with red-green-blue (RGB) cameras, which only capture the size, shape and visible colors of objects.

Hyperspectral cameras have already been explored and successfully used in several sectors, including in agriculture, the oil and gas industry, the shipping industry and marine archaeology (to name a few). It therefore looked promising to our teams.

A dozen rusty metallic tower samples were sent to the partners, who, over the course of a few months, tested and then analysed them, seeking to classify the severity of different rust patches, understand the oxidation process and its properties, and undertake an initial assessment of the feasibility of using Hyperspectral as part of metallic tower inspections. These tests allowed us to validate initial hypothesis and led us to better understand its constraints and possible improvement opportunities.

Next steps

Given the promising results obtained during the laboratory tests in 2022, we are now planning to test the technology outside, in the field - with a view to possibly mount the camera on drones, too. The main focus of this second phase of the innovation project will be to validate and develop further the below points:

- Validate technical feasibility of the camera used in the field, especially understand influence of light, background colors, and distance to object

- Further develop algorithm for rust classification of hyperspectral images;

- Create payload prototype for mounting on drone and continue test with data captured in the field;

- Drone integration and validation including ready to use MVP.

Partners

|

|

|